Newly equipped

4 Noteworthy Features

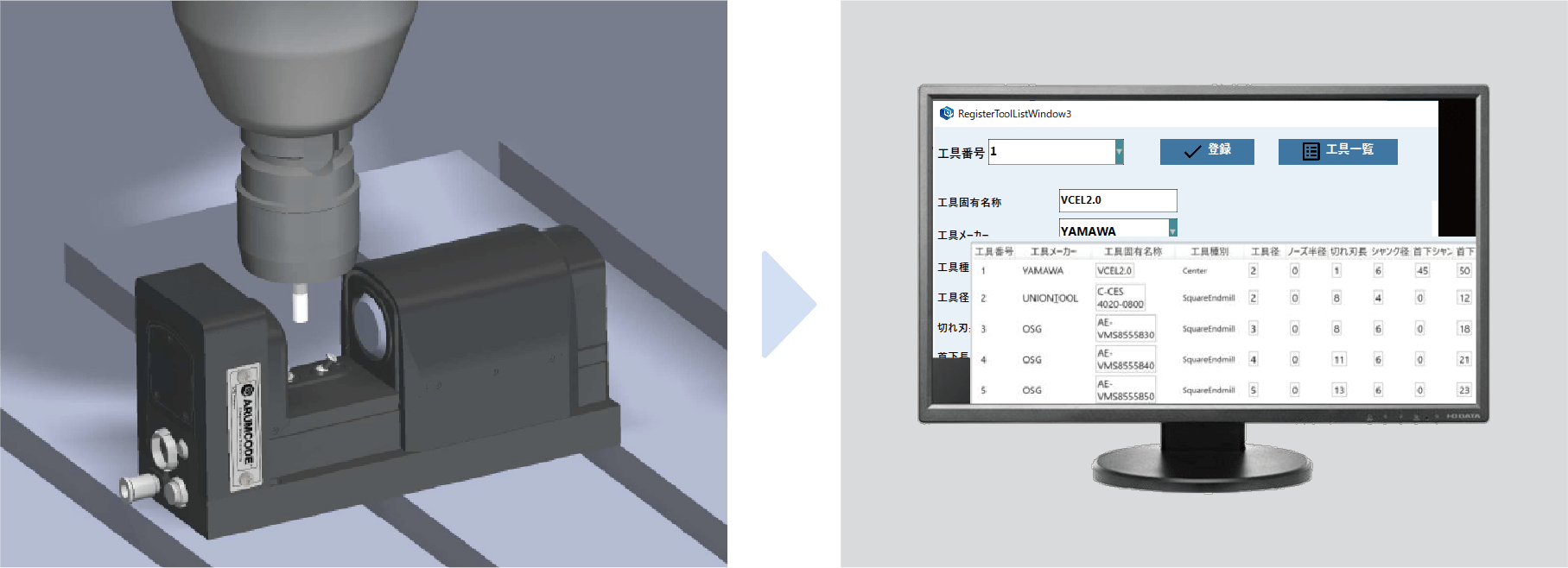

50% reduction in tool-related setup time

Automatic measurement of tool diameter and length with our self-developed camera unit and tool length with our self-developed camera unit.

Automatic correction of cutting conditions based on measured tool information.

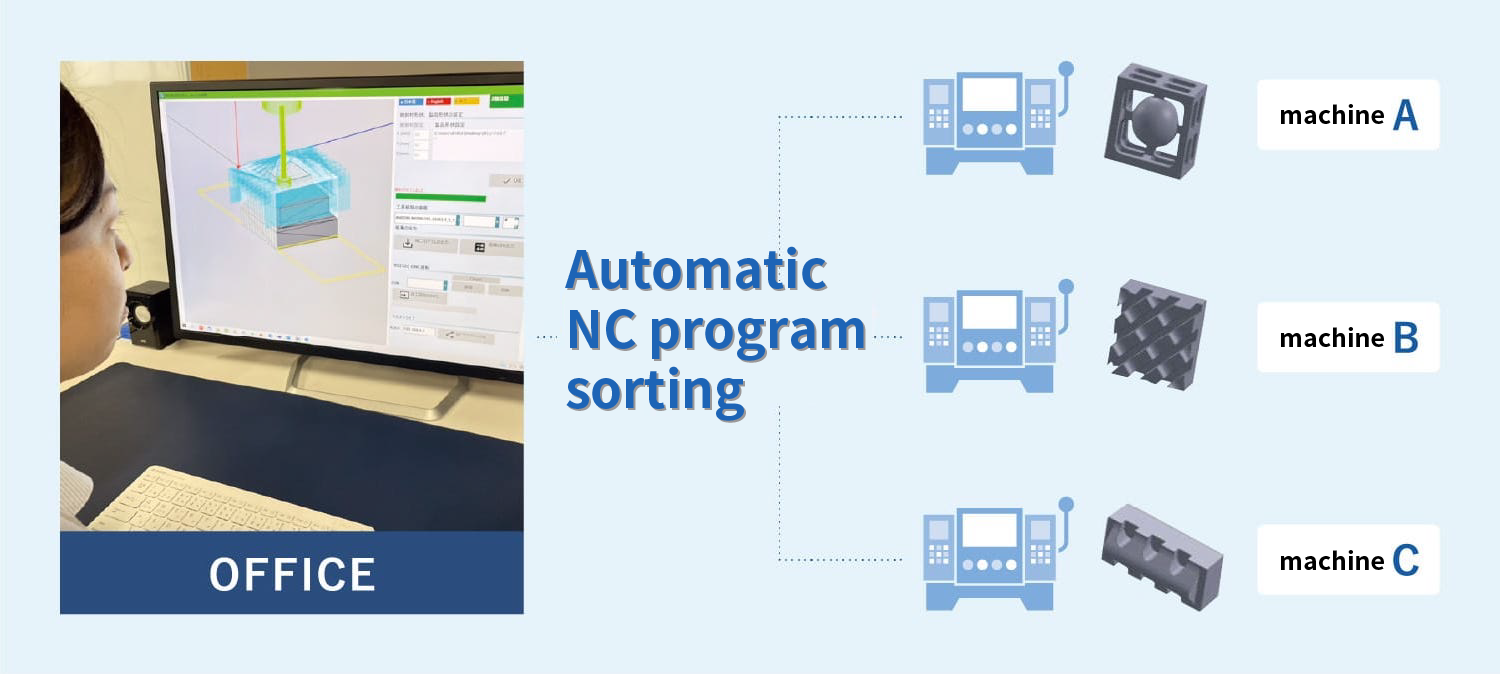

Simultaneous machining of multiple parts to increase machine utilization

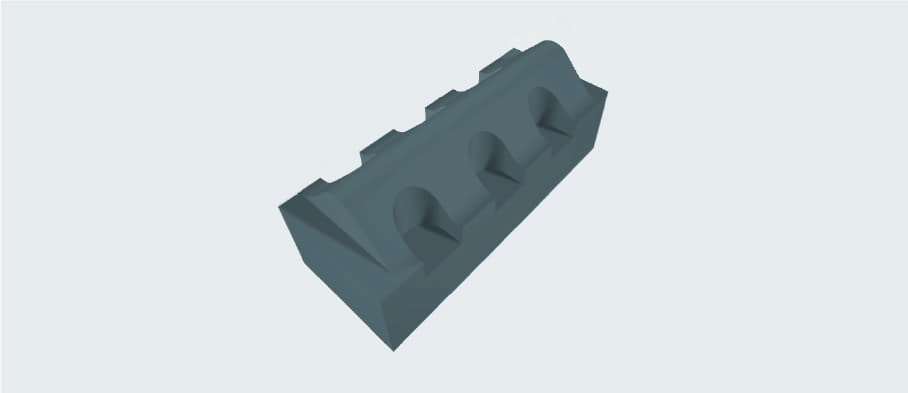

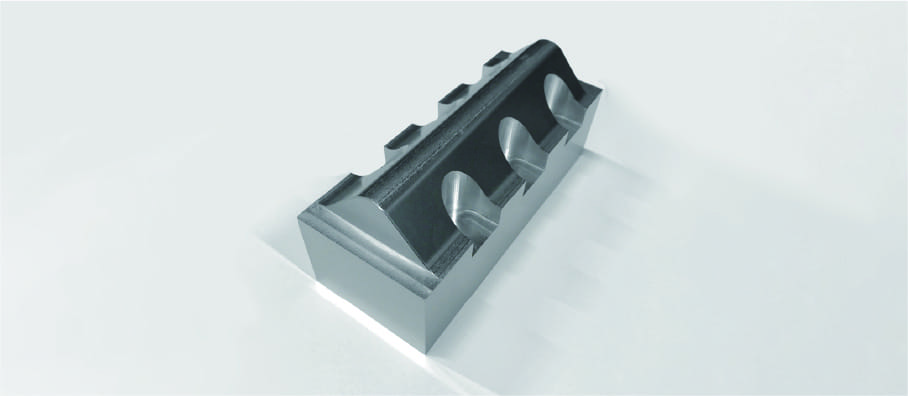

Supports 2.5D machining including XZ and YZ directions, such as flow curve shapes and press/mold dies

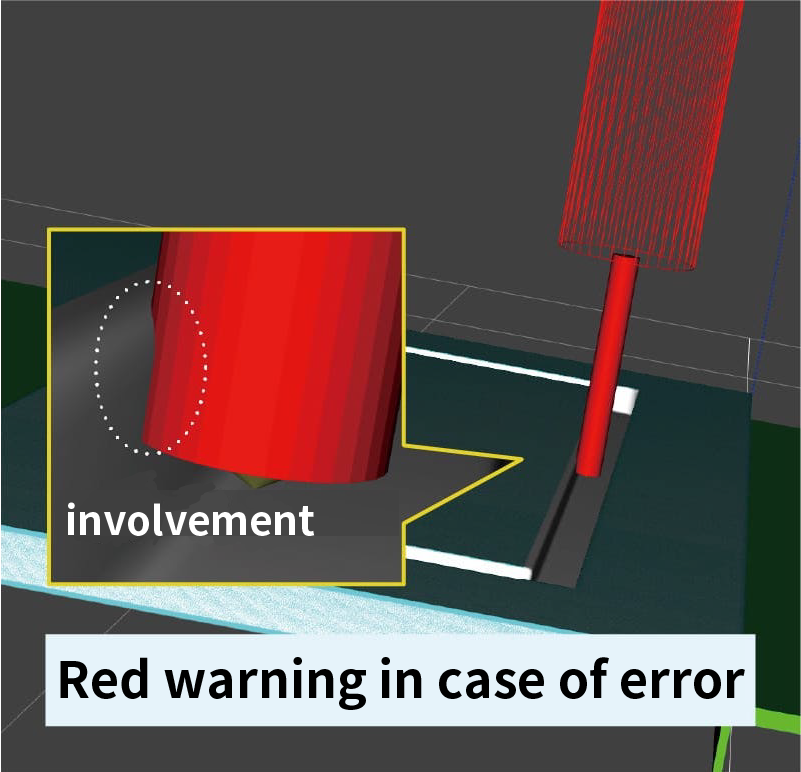

Tool interference check in advance for safe and secure machining

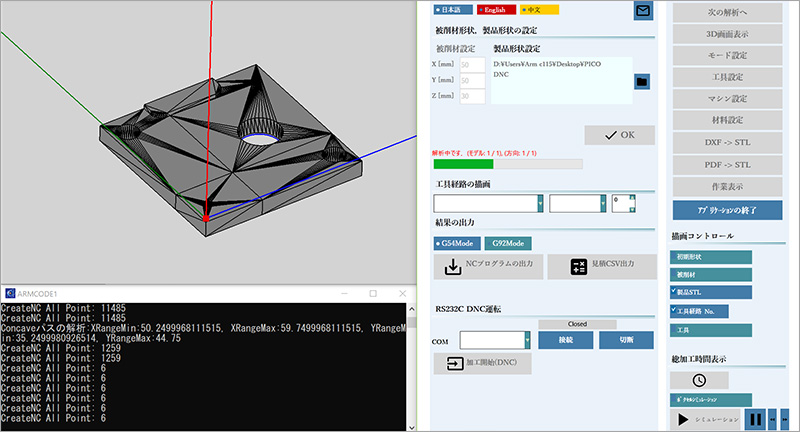

ARUMCODE1 analyzes the shape of machined parts by simply dragging and dropping drawing data.

Tool selection accordingly, setting of machining conditions and indication of material and tool set instructions are performed instantly.

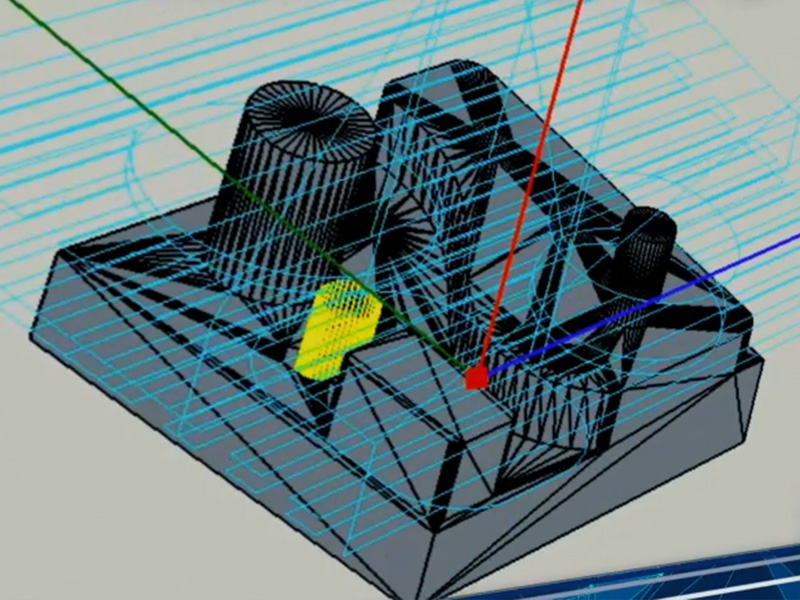

The Z-axis is thinly sliced and the feature area is analyzed based on the coordinate values obtained at a pitch of 5 microns in the XY plane.

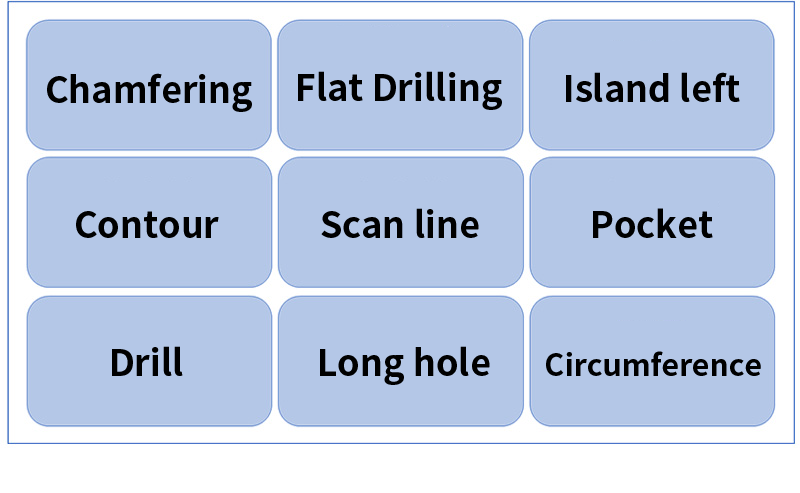

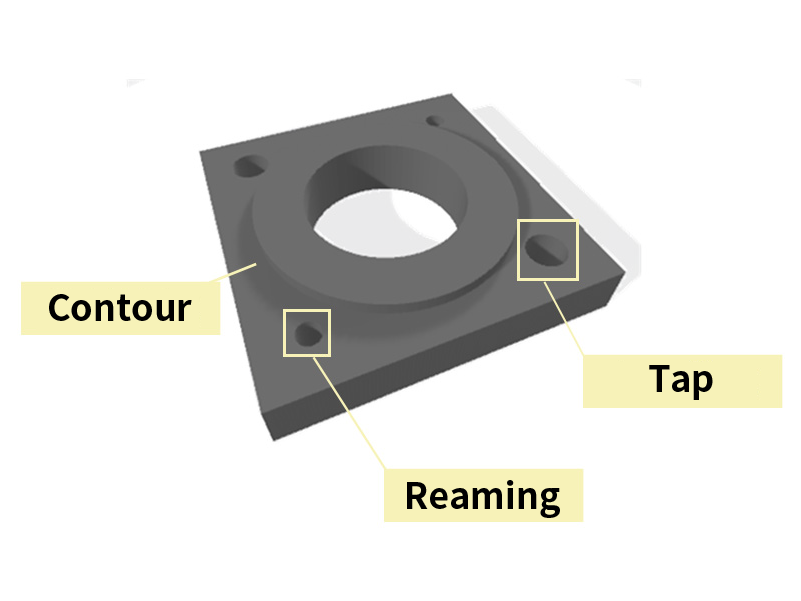

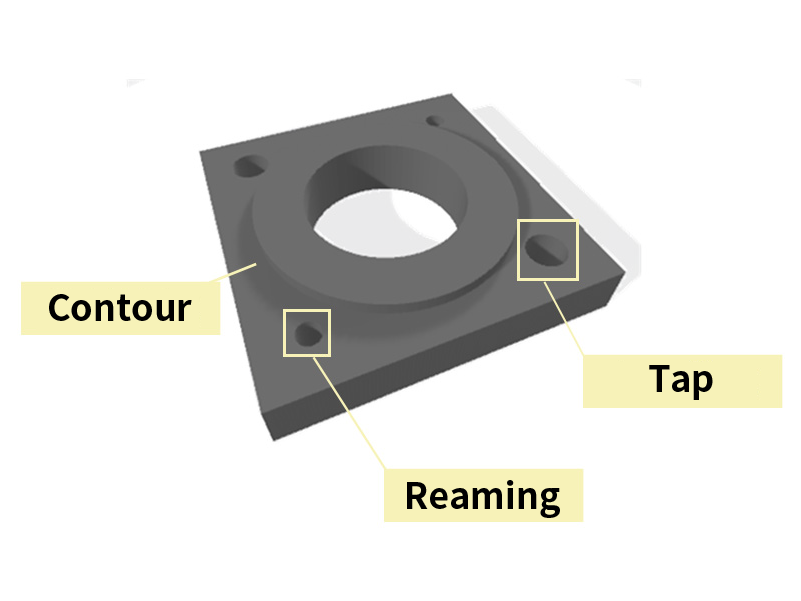

The system automatically determines where and what kind of machining to do according to the shape of the analyzed drawing data.

※ A portion of the actual allocation is shown.

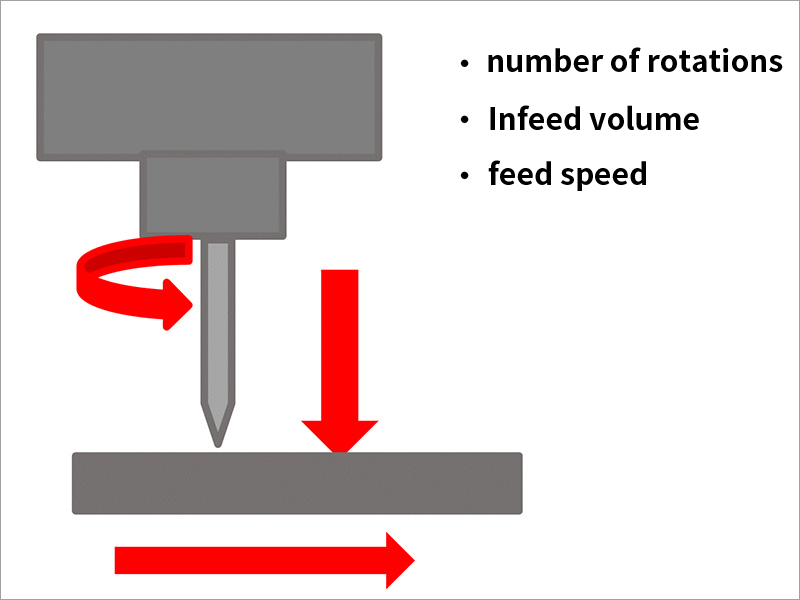

Based on the machining allocation data and tool information registered at the time of ARUMCODE1 installation, the optimal tool for each machining is automatically set.

Optimal machining conditions are calculated at high speed according to a proprietary algorithm based on your machine information (model, depreciation age, etc.), tool, and material information registered in ARUMCODE1.

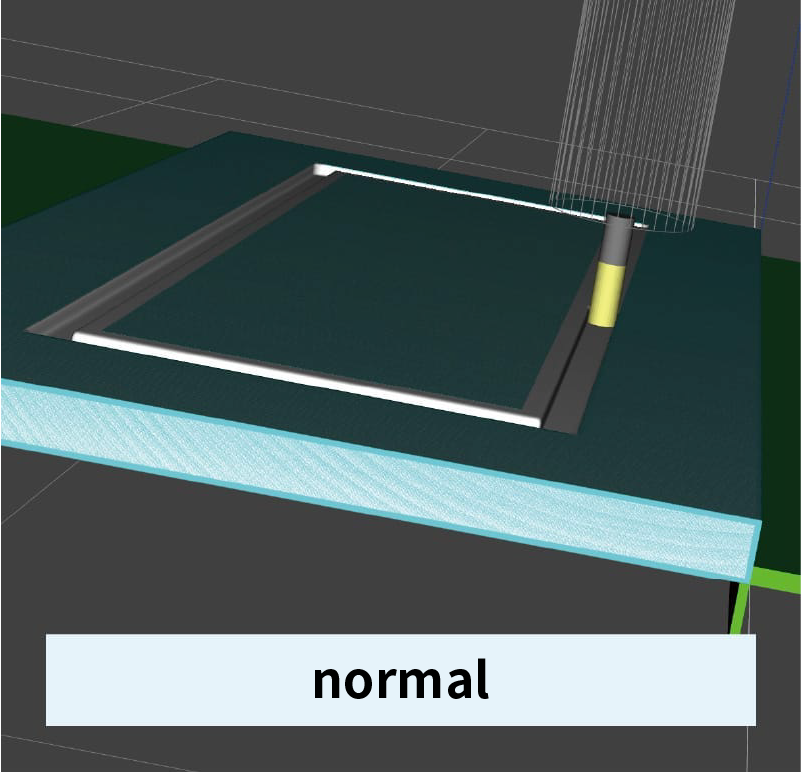

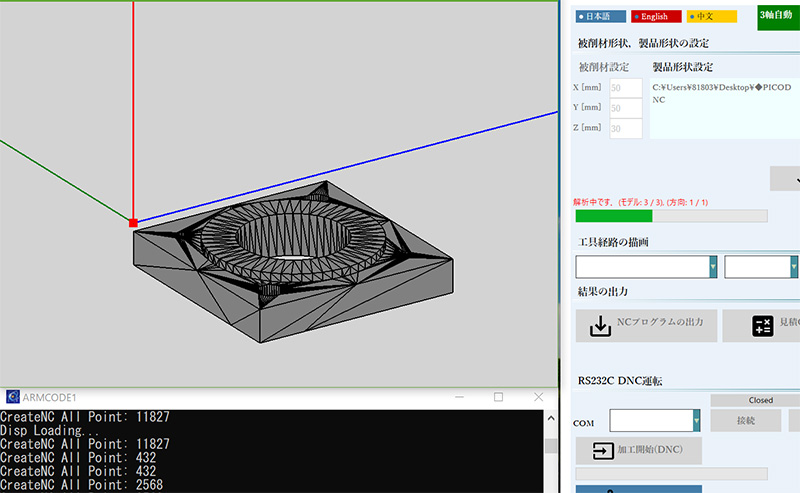

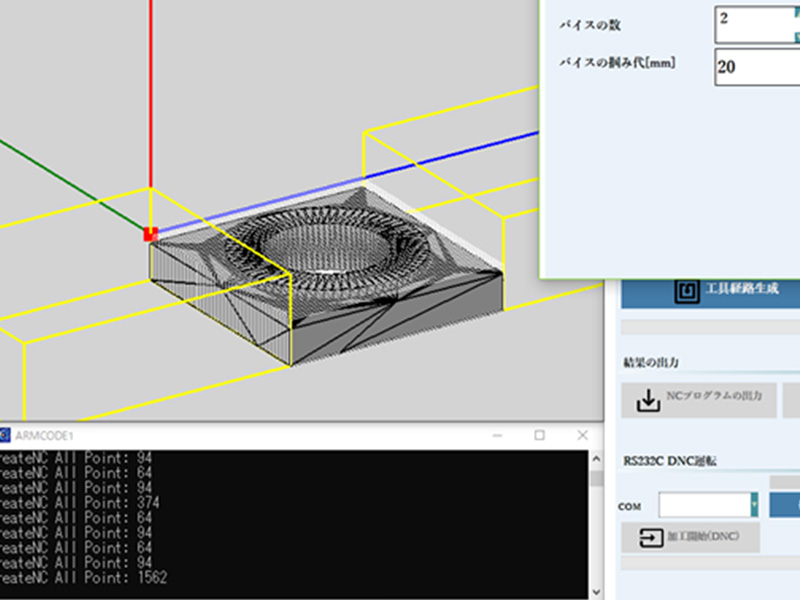

Based on the set machining conditions, an efficient machining path is automatically calculated and a machining simulation can be drawn.

In addition, by pre-registering information on the number of vises and gripping allowance (in mm), the model viewer can confirm such information.

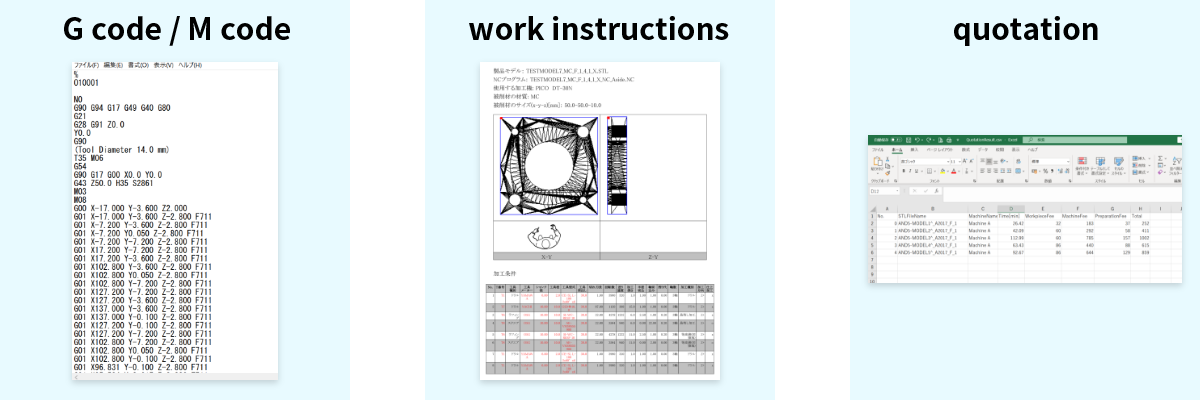

Based on the information up to this point, a processing program is automatically created.

It also produces work instructions and quotation information that describes the tools used and machining conditions.

For more detailed information, please request a product catalog.

The claim Click here

| name of company | ARUM Inc. |

|---|---|

| representative | HIRAYAMA TAKAYUKI |

| Establishment | August 2006 |

| capital stock | 48 million yen (Subsidiary O.S.E.: 70 million yen) |

| Location | 1-61, Tomizu, Kanazawa, Ishikawa 920-8204, Japan Google Map |

| Main Banks | Hokkoku Bank |

| Automation Business | ・Research and development of manufacturing AI ・Design and manufacture of various industrial machinery ・Design and manufacture of various specialized machines ・Design and manufacture of other automation-compatible equipment ・Ultra-precision parts processing |

| key customers | ・Automobile and automotive parts manufacturers ・Electronic component manufacturers ・Measuring instrument manufacturers ・Machine tool manufacturers ・Mold and press die makers ・Manufacturers of heavy machinery 150 other companies |

| Contact | TEL:076-225-7743 FAX:076-225-7783 |

| domestic locations (e.g. of a company) | O.S.E. Corporation (100% capitalized by ARUM) Address:1-28, Koku-cho Oyachi, Iijima, Akita City, Akita Prefecture, 011-0916, Japan TEL:018-846-8250/FAX:018-847-1977 Ultra-precision parts machining, FA equipment design and manufacturing External Sites:O.S.E. Corporation http://www.akita-ose.co.jp |