Manufacturing Revolution

through Production AI & Full Automation Tech

DAYS

HOURS

MINUTES

SECONDS

Service launch on 1 July 2023

The award-winning ARUMCODE series has finally available on subscription!

Early Reservation Form

Please complete the form below.

Three challenges faced by small-lot parts manufacturing companies

- 1

Limits to cost reduction

Shortage of skilled workers and rising prices make further cost reductions difficult

- 2

Ageing of skilled workers and Lack of young people

With an ageing workforce of skilled workers and few young employees, there is a lack of personnel who can pass on the know-how that the company has developed over the years.

- 3

Management of IT tools is cumbersome

When various IT tools are introduced, the data management for each tool is also different, which increases the workload and makes it even more cumbersome.

Revolutionise your factory with ARUM Factory365

- 1

CNC programming automation for overwhelming cost reductions

- 2

Transfer of the machining know-how of skilled workers to the next generation to exclude dependency on individual skills

- 3

Centralisation of all the IT solutions required for manufacturing management

CNC programming automation for overwhelming cost reductions

Automatic CNC programme generation AI "ARUMCODE"

Automatic CNC programme generation

CNC programmes that have been created manually can be generated fully automatically. It frees one programmer from long hours of NC programming work with CAM.

Two simple steps to select and start

Select the 3D CAD data in STL format you want to programme and click Start. With just this, anyone can easily create an NC programme, even if they have no machining experience.

Easy and simple initial setup

You can register for use with a Microsoft or Google account and be operational on the same day. There are no cumbersome order forms or paperwork to deal with.

Any time, any place, any device.

As a cloud service, data can be uploaded not only from a PC, but also from a smartphone or tablet.NC programmes can be output without depending on the environment, such as when you are out of the office or working remotely.

Compatible with a wide range of processing methods, materials and machine types

It supports 3-axis and 5-axis milling.

*Support for turning, grinding and casting will be added in due course.

Materials supported include various types of aluminium, copper, resin, carbon steel and general structural steel.

*A2000, 5000-7000 series, S45C, S50C, SS400, SUS303, 316, etc.

*Recommended workpiece size: max. 2,000 mm x 1,000 mm x 50 mm

Compatible with almost all machine manufacturers worldwide and can be operated on their own machines.

*Compatible NC controls: FANUC, Mitsubishi Electric (Merdus), SIEMENS

Surprisingly easy to edit machine post-processor

You can easily edit post-processors in-house, reducing the time and cost of outsourcing post-processor support.

Go to top

Transfer of the machining know-how of skilled workers to the next generation to exclude dependency on individual skills

The 'library' for digitalising the unique machining know-how accumulated in your factory.

You can customise ARUMCODE to your own specifications or pass on your company's manufacturing know-how to the next generation.

Digitisation of skilled workers' know-how

Your company's know-how and knowledge of materials, tools and other machining conditions is digitised as a 'library'.

By digitising the 'intuition and tricks' in the minds of skilled workers as numerical data, the know-how developed over many years can be passed on within the company as 'information assets'.

ARUMCODE can be customised to your own specifications

Customise ARUMCODE to your own specifications by creating a library of know-how specific to your company. This enables the automatic generation of NC programmes that reflect the conditions under which the company has been machining.

Libraries in partnership with manufacturers

For example, we have tied up with tool manufacturers around the world to provide a library of data on the optimum cutting conditions recommended by the manufacturer. This eliminates the need to search for the recommended cutting conditions for the tools used in your company from a vast amount of catalogue data and input the condition data for each tool individually.

You can choose the scope of publication according to your needs

If you don't want your factory's know-how to disappear but don't want to share it with other companies, you can use it exclusively for your own use as a 'private' library. If you want to share the library only within your own affiliated companies and keep the quality constant, you can use it only between specific companies as a 'limited public' library. If you want to sell your own know-how, you can make the library 'fully public'.

In this way, you can select the publication range of the library in three levels according to your objectives.

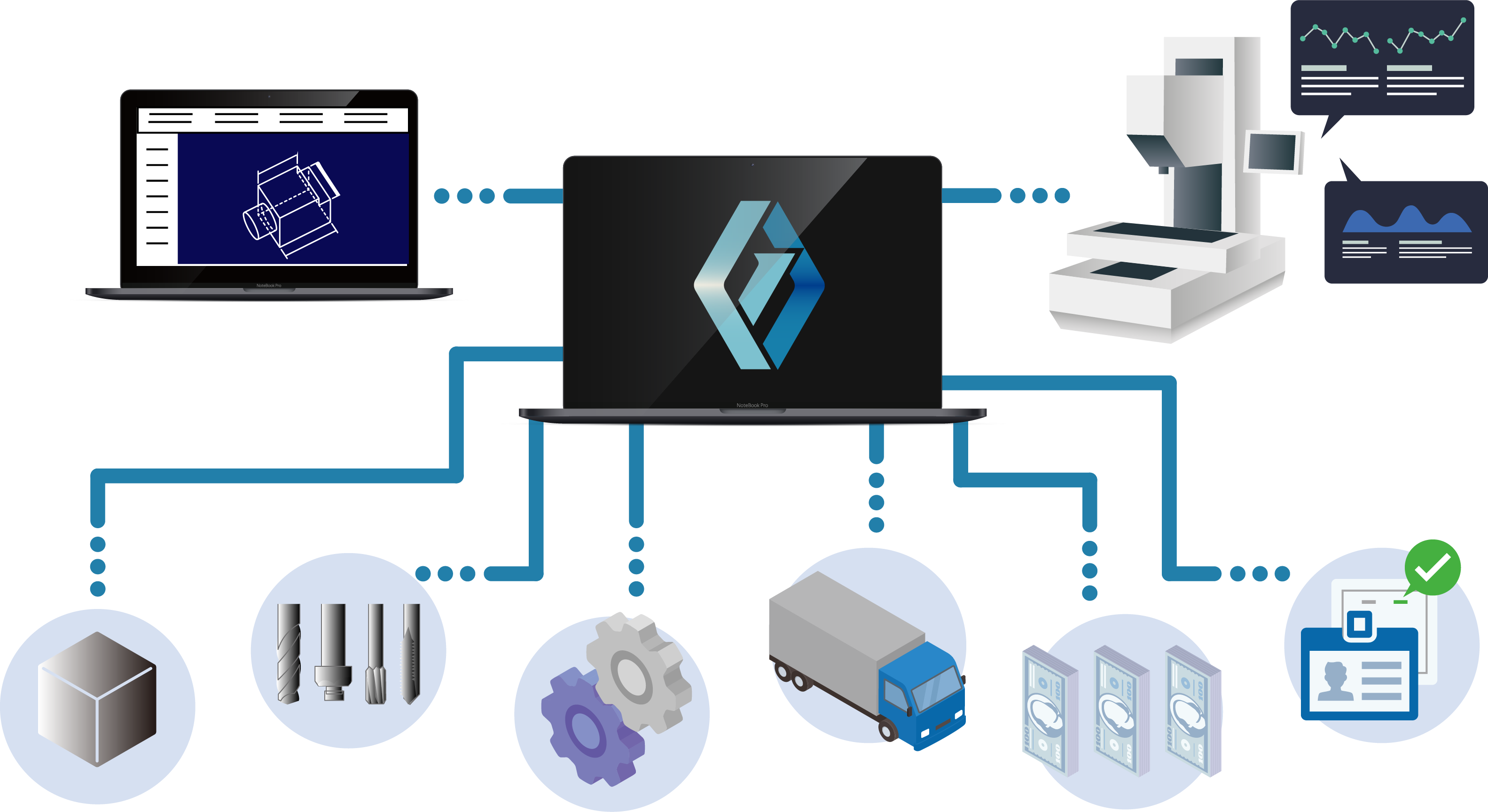

Centralisation of all the IT solutions required for manufacturing management

Innovative platform for precision parts manufacturing companies integrating various software and hardware solutions

Provides a variety of solutions on a single platform to reduce the burden on manufacturing sites

In addition to data management related to the engineering chain, such as 3D CAD, precision measuring instruments and production management systems, various tools required at manufacturing sites, such as online ordering systems for tools and materials, shipping arrangements and profitability analysis tools, will be provided sequentially on the ARUM Factory365 platform.

This will free you from the inefficient and tedious administrative work of managing data from various IT tools in a disjointed way!

Strict management of important data entrusted by the client

ARUM Factory365 uses Microsoft Azure, the world's most secure cloud service provided by Microsoft. Data is encrypted with high precision, making it unreadable even in the event of unauthorised access.

The important data provided by the client is thus securely protected.

Tariff plans

339.99 € per month

Initial setup fee0€Maintenance fee0€PREMIUM

- Unlimited use of all ARUMCODE series apps

- Data usage fees (pay-as-you-go)

129.99 € per GB - Library usage fees (pay-as-you-go)

49.99 € per library - Cloud data security with Microsoft Azure trusted by most Fortune 500 companies

- Free tools for easy post-processor editing are provided

- Remote support by engineers

- Priority analysis during access concentration

- Advance use of test versions of pre-release apps

169.99 € per month

Initial setup fee0€Maintenance fee0€STANDARD

- Unlimited use of all ARUMCODE series apps

- Data usage fees (pay-as-you-go)

129.99 € per GB - Library usage fees (pay-as-you-go)

49.99 € per library - Cloud data security with Microsoft Azure trusted by most Fortune 500 companies

- Free tools for easy post-processor editing are provided

- Email support (reply within 5 working days)

6 steps to start using the service

STEP01

Apply for the early registration campaign

After completing your application, we will confirm your registration information by email.

STEP02

Payment URL will be sent to your registered email address (scheduled for early July).

STEP03

Log in with your Microsoft or Google account.

STEP04

Select a plan

Select either the Premium or Standard plan.

STEP05

Enter payment information

You can pay by bank debit or credit card (Visa, Mastercard, JCB, American Express, China UnionPay (CUP), Discover and Diners).

A receipt will be sent to your registered e-mail address after the payment is completed.STEP06

Registration complete! From July 2023, you can start using the service.

Enjoy the cutting-edge digital manufacturing services with two early registration offers: 2 months free 1GB data usage and 2 months free 1 library usage.

Early Reservation Form

Please complete the form below.

FAQs

- What is ARUM Factory365?

ARUM Factory365 is digital manufacturing services that offer manufacturers and small-lot precision parts production SMEs unlimited use of NC programming automation apps, a library creation kit to customise machining conditions to their own specifications, and easy post-processor editor.

- What are the subscription fees?

There are two plans available: the Standard Plan for a basic monthly fee of 169,99 € and the Premium Plan for 339.99 €. The entire ARUMCODE series of automatic NC programme generation apps is available for unlimited use. There is also a pay-as-you-go data usage fee (129.99 € per GB) and a library usage fee (49.99 € per library).

- What support do we offer?

Email enquiries are replied to within 5 working days. For customers who subscribe to the Premium plan, we offer remote support via the web or other means by our engineers.

- How can you start using the service?

The ARUM Factory365 procedure is very simple. There are no cumbersome contracts, annual licences or other restraints. With just a few clicks, you can easily start the service online.

- How can you cancel your services?

The cancellation procedure for ARUM Factory365 is very simple. There are no cumbersome forms and no time constraints on the period of use. With just a few clicks, you can easily cancel online at any time. There are no cancellation fees and you can start or cancel your account at any time.

- What CNC machines and materials are supported?

[Supported machines] Almost 100% of machine tools with CNC controls from FANUC, Mitsubishi Electric (MERDUS) and SIEMENS can be used by any manufacturer in the world.

[Supported materials] Various types of aluminium, copper, resin, carbon steel and general structural steel materials.

(A2000, 5000-7000 series, S45C, S50C, SS400, SUS303, 316, etc.)

[Recommended workpiece size] Max. 2,000 mm x 1,000 mm x 50 mm